Hydraulic Ball Valve

Hydraulic Ball Valve

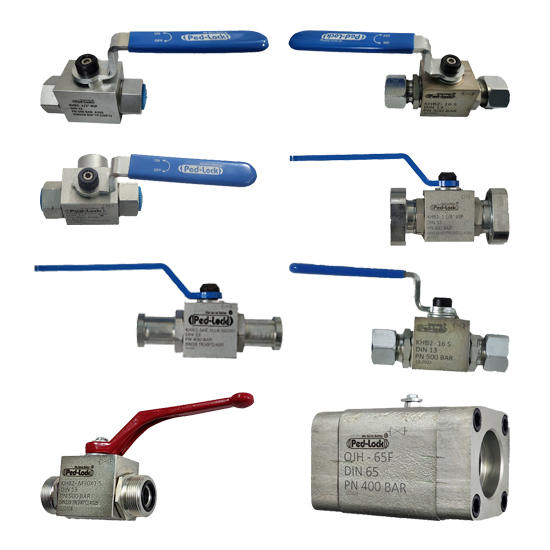

Hydraulic Ball Valve Manufacturer in India makes ball valves of different types and material makes. The type of the valve can vary according to the operating procedure, the pressure capacity, and the number of components it could control. The Stainless Steel Hydraulic Ball Valve is the most used in terms of material. There are 304 and 316 types of austenitic stainless steels that are used most commonly for the production of these ball valves. The High-Pressure Hydraulic Ball Valves are applied in high-pressure systems such as pressure vessels. There are Two-Way Ball Valves and 3 Way Ball Valves. The 2-way ball valve connects only two lines. The 3-way hydraulic ball valve connects 3 lines it can regulate the inflow and outflow of different components through the valve.

The valve consists of a ball-shaped valve inside a body that is connected to a handwheel with an axis. The axis or stem of the ball valve rotates the valve mostly at 90-degree angles so that the valve is either in the fully open or fully closed position. The 3000 psi Hydraulic Ball Valve is one of the high-pressure valves. The valve pressure capacities range from 150psi to 9000psi depending on the material make and the application. There are different types of ball valves such as the hydraulic actuated ball valve and others. Larger valves can also have more positions with planetary type gears to precisely control the flow. However, the hydraulic shutoff valve is the most common that is used to either fully open or close the valve.

| Rating | Up to 7,000 psi @ up to 180ºF |

|---|---|

| Stem & Body Seal | ‘O-ring (Nitrile & Viton) |

| Seat Packing | Ptfe & Peek |

| Tube Size | 1/4” to 2” |

| Connections | Threaded |

| Body | Bar Stoke & Forged Steel |

| Material | SS, and other Material Other as Per Your Requirements |

Application

- Chemicals industry

- Food Fats and fertilizer industry

- Ship building

- Construction industry

Physical Features

- Pressure rating 500 kg/cm2

Testing

- For seat and seal leakage with a leakage rate of 0.1 std. Cm3.

- Working pressure: 7000 psi (500 bar)

Hydro Tests

- Performed with pure water at 1-1/2 times of the working pressure.

- Other tests like helium, seismic are available upon request.

Key Features

- SS 316 construction for corrosion resistance, full or reduced bore for excellent flow. Peek/delrin seat for better performance.

- Ball hard chrome plated for smooth operation.